Air Actuating Devices Explained: An Important Manual Override Function

In the world of automated systems and control systems, pneumatic actuators play a vital role by converting compressed air into physical motion. These devices are extensively used in multiple industries, from production to aviation, due to their reliability and effectiveness. However, like all mechanical component, they can occasionally face issues or require manual intervention. This is where the concept of a pneumatic actuator with manual control override becomes essential.

A pneumatic actuator with manual override allows operators to assume control of the system in situations where automated functions may not be possible. Whether for air and manual actuator , urgent shutdowns, or troubleshooting, this feature guarantees that operators can safely and efficiently manage the system. Understanding how these actuators work and the significance of the manual override feature can enable users to make wise decisions about their automation needs.

Comprehending Air-powered Actuators

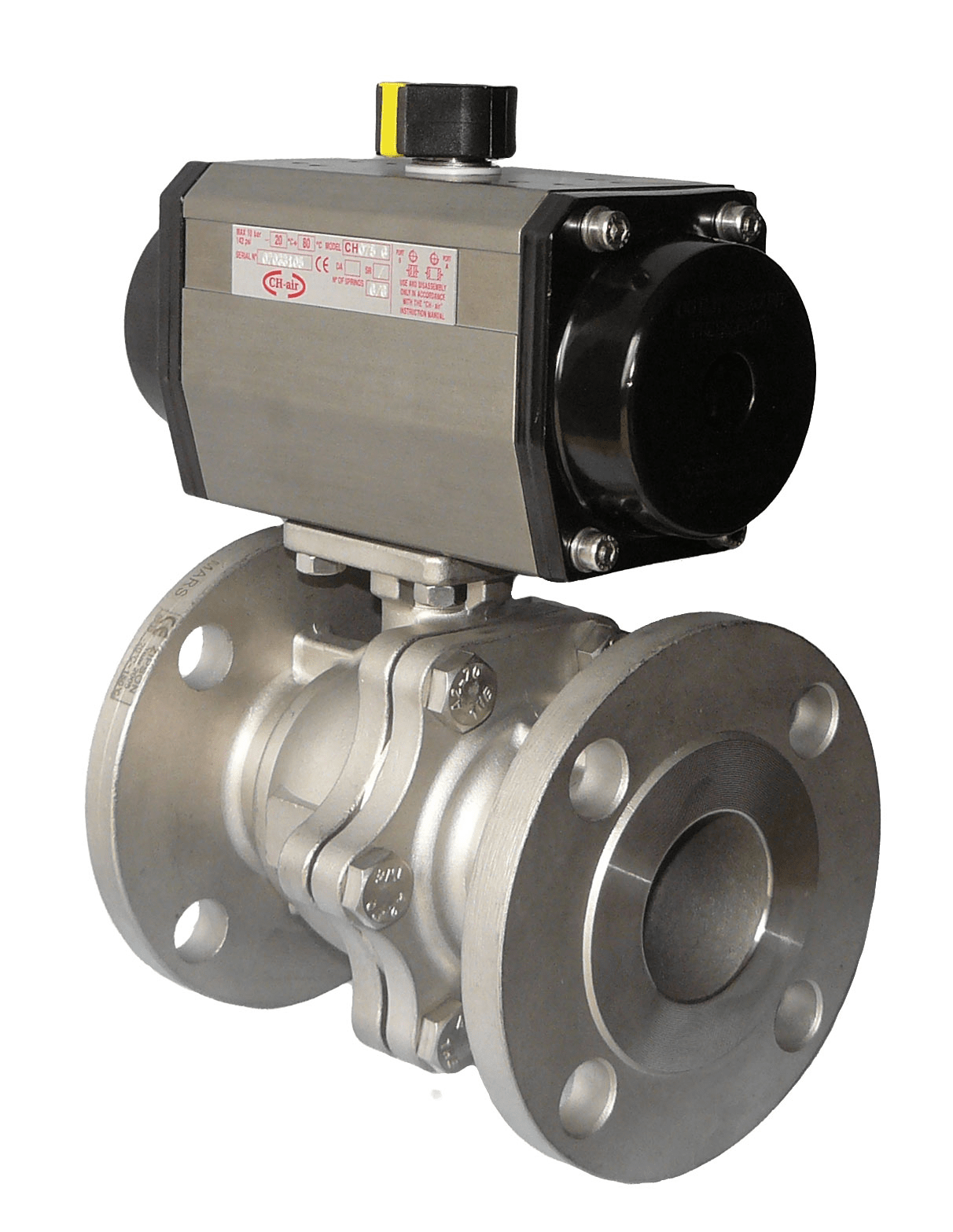

Compressed air devices are components which convert pressurized air into physical movement, chiefly utilized for move & manage machinery in various factory applications. They operate by utilizing the force of the compressed air delivered into them, that drives a cylinder element or diaphragm within a tube. This motion is later employed for powering valves, regulators, & additional equipment, making pneumatic actuators vital components in automatic processes.

The configuration of pneumatic actuators can vary, but they usually comprise a chamber, a piston, along with a supply network for the compressed air. When air fills the chamber, it pushes the piston, creating linear or circular movement depending on the actuator's configuration. One of the main advantages of pneumatic actuators lies in their quick response speed, which renders them ideal for applications that require rapid movement and management.

In numerous cases, it can be essential to have a manual override mechanism built-in into pneumatic devices. This enables operators to control the device directly in instances where automatic control might fail or when a specific manual operation adjustment is needed. The physical override ensures that operators can maintain oversight over processes and systems, improving safety and reliability in diverse manufacturing settings.

The Importance of Manual Override Control

Operator control is a critical feature in pneumatic actuators, providing operators with the ability to maintain control in situations where automatic operation may malfunction or become unreliable. This functionality ensures that processes can continue efficiently, even in the event of a power failure or mechanical malfunction. By enabling for manual control, operators can intervene and prevent costly downtime, ensuring the safe and effective operation of equipment and systems.

In settings where pneumatic actuators are used, unexpected conditions can arise that disrupt normal functioning. Manual control allows for rapid response to crises, enabling operators to safely adjust the actuator's position and maintain operational integrity. This feature is particularly vital in applications where automated systems might prejudice safety, as it enables users to take charge of the situation and make timely actions.

In addition, the inclusion of a manual control enhances the versatility and reliability of pneumatic actuators. It provides operators with assurance that they can manage the machinery effectively, reinforcing safety protocols and operational efficiency. The ability to switch from automatic to manual control plays an essential role in the overall resilience of systems that depend on pneumatic actuators, ultimately contributing to improved output and reduced risk.

Uses and Recommended Practices

Pneumatic actuators with hand-operated override are extremely adaptable and find uses across multiple industries including production, automotive, and aerospace. In robotic production lines, these actuators are used to manage gates and shutters, permitting precise control of liquid and gaseous flow. The manual control feature is essential in these settings, permitting operators to take immediate control in case of system breakdowns or critical events, ensuring protection and operational continuity.

In the vehicle industry, pneumatic actuators are often used in systems that require rapid response times. For example, they can control functions such as stopping and suspension tweaks. The capacity to take control of the pneumatic actuator can make troubleshooting easier, enabling technicians to diagnose problems or perform maintenance without needing to rely entirely on the automated system. This not only enhances effectiveness but also improves safety in vehicles.

To maximize the effectiveness of pneumatic actuators with hand-operated override, it is important to follow best practices. Regular upkeep and inspections should be conducted to ensure that both the manual and automatic functions are operating properly. Operators should be educated on how to alternate between robotic and hand-operated control effectively, including knowing the constraints of manual override. Additionally, correct pressure parameters should be maintained to ensure steady performance and reliability in various operational conditions.